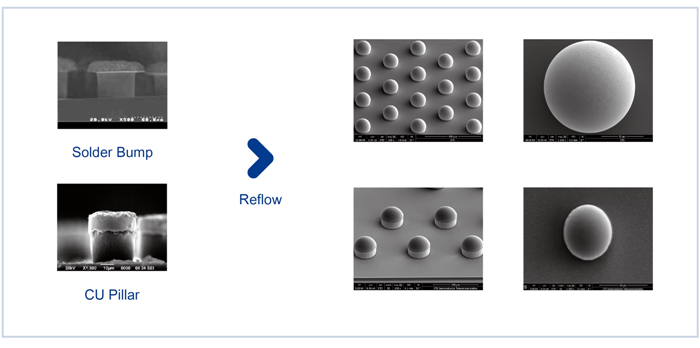

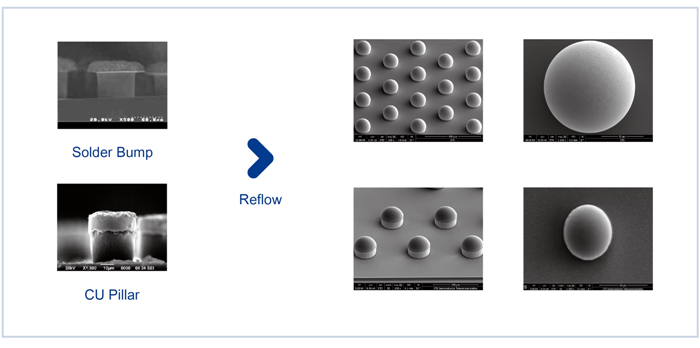

STI SRS30V is the equipment for forming bumps and flip chips using heat in semiconductor packaging process.

【Features】

- Void-free Bump Ball Performance

- Various Temperature Profile (Step & Slope Type)

- Outstanding O2 Density Control(<1ppm) at Every Process

- Conduction & Convection Heating Chamber System

- No Chip Sliding on the Flip Chip Process

- Temp Control : 250±1% (Max.450℃) Real Time Monitoring of Process Wafer Temp.

- Process gas : Formic acid or no Reactant gas

- Process Pressure : Vaccum / ATM Process

- EFEM(2 or 3 Port) : SEMI Standards

【Application】

- Fluxless Reflow for solder Bump Ball, Cu pillar & CoW Chip Bonding of the HBM

- Vacuum or ATM Reflow System

STI produces advanced CCSS (Central Chemical Supply System) equipment and wet process equipment (Cleaner / Developer / Etcher / Stripper) for Semiconductor and FPD industry. Besides CCSS and wet process, STI's product range also includes special LCD, inkjet, reflow and wet blast system. STI is leading the CCSS business in Korea and many customers recognize STI's technical competitiveness.