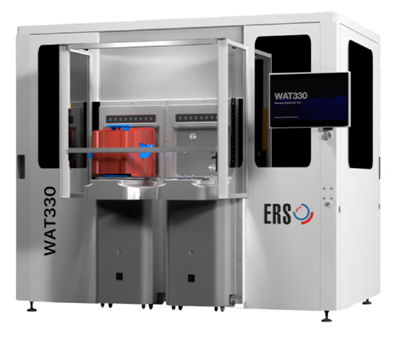

The ERS WAT 330 is a fully automatic tool for the thermal forming of 300/330mm FOWLP wafers. The specially-designed ERS TriTemp Slide® in this system makes it possible to successfully form a wide variety of FOWLP wafers at various stages in their processing and the resulting wafer shape can be matched to the handling specifications of the downstream tool.

The ERS WAT 330 is able to process up to four FOUPs in a fully-automatic operation. It is equipped with a Wafer-ID reader and an automatic warpage measurement station that enables a high flexibility with 3 separate operation modes. It can be used strictly as a warpage measurement station, as a warpage adjustment station, or as a warpage measure/adjust/monitor station.

The upgraded WAT330 comes with a HEPA filter system for cleanroom class 100. It is also fully compliant with the GEM300 SEMI standards and compatible with automated product loading and unloading. Another upgrade is the machine’s Nitrogen environment, which can reach down to 0.5% O2 level to avoid Cu oxidation. The new WAT330 also features strong vacuum thermal chucks for no-fail wafer handling.

|

WAT 规格

|

|

|---|---|

|

Wafer Size

|

200 mm or 300/330 mm

|

|

Handling System

|

One 4-Axis Robot; special endeffector

|

|

Maximum Input Warpage

|

± 7mm

|

|

Warpage Adjust Method

|

ERS TriTemp Slide

|

|

Typical Output Warpage

|

< 500µm

|

|

Temperature Control

|

DC PID and ERS AirCool® components

|

|

Temperature Range

|

-10°C up to +260°C (depending on station)

|

|

Oxygen Free Environment

|

Optional

|

|

W x D x H

|

2273 x 1134 x 1741 mm

|

|

Weight

|

1800kg

|

|

设施项目

|

规格

|

|---|---|

|

Voltage

|

400 VAC 3-phase 32A

|

|

Frequency

|

50 / 60 Hz

|

|

Power

|

18 kW

|

|

CDA Pressure

|

6 bar at 0 °C dew point

|

|

CDA Flow Rate

|

1000 l/min peak

|

|

Vacuum Pressure

|

100 mbar

|

|

Vacuum Flow Rate

|

100 l/min

|

ERS electronic GmbH, based in Munich, has been producing innovative thermal test solutions for the semiconductor industry for 50 years. Today, thermal chuck systems developed by ERS in its product families; AC3, AirCool©, AirCool© Plus and PowerSense© are an integral component in all larger-sized wafer probers across the semiconductor industry. ERS also developed eWLB series for warpage adjustment, and has kept making technology progress and improvements over a decade.